In pharmaceutical manufacturing, controlling contamination is crucial for obtaining reliable results and ensuring product safety. Two essential pieces of equipment widely used to maintain sterile working conditions are Laminar Airflow Cabinets and Biosafety Cabinets. They may appear similar at first glance, but they serve distinct purposes and offer different levels of protection to the sample, the operator, and the environment.

Let’s explore the fundamental concepts behind laminar airflow cabinets and biosafety cabinets, their mechanisms of action, detailed classifications, and typical applications. By the end of this article, you will be able to differentiate these cabinets and understand their appropriate use.

What is a Laminar Airflow Cabinet?

The key component enabling sterile conditions inside a laminar airflow cabinet is the High-Efficiency Particulate Air (HEPA) filter. These filters are highly efficient in trapping airborne particles of 0.3 microns in size, which includes most bacteria, fungal spores, and particulate contaminants.

Here is a breakdown of the airflow process inside the cabinet:

- Air Intake: A blower or fan mechanism will draw the Ambient air into the cabinet.

- Pre-Filtration: The air passes through coarse or pre-filters that trap large dust and particles.

- HEPA Filtration: The pre-filtered air forcefully enters through the HEPA filter, which removes at least 99.97% of particles ≥0.3 microns.

- Unidirectional Airflow: The filtered, sterile air enters the work surface in a laminar (smooth, parallel) flow pattern.

- Air Exit: After passing over the work area, the air moves toward the operator or exits the cabinet.

This continuous flow of sterile air helps to flush away contaminants from the workspace, maintaining an aseptic environment.

Types of Laminar Airflow Cabinets

Laminar airflow cabinets can be broadly classified based on the direction of the airflow inside the cabinet:

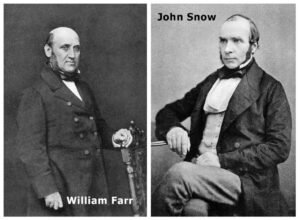

1. Vertical Laminar Airflow Cabinets

In these cabinets, the sterile filtered air flows vertically downwards from the top of the cabinet toward the work surface and then out toward the operator. This vertical flow creates a sterile environment directly over the work area.

Vertical laminar airflow cabinets are useful for sterile pharmaceutical compounding, tissue culture work, and other applications requiring a contamination-free work surface.

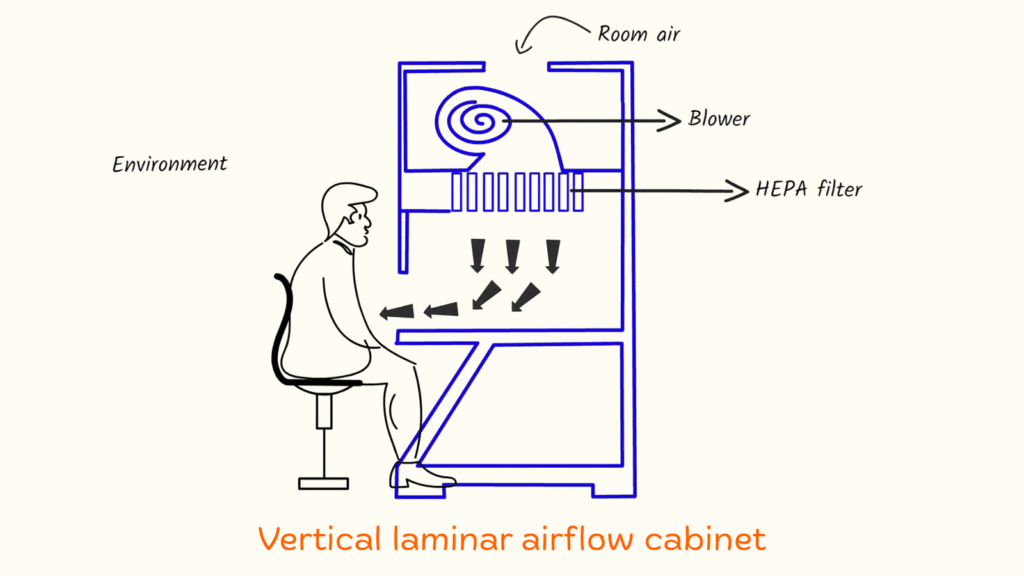

2. Horizontal Laminar Airflow Cabinets

In this design, air passes horizontally from the rear of the cabinet toward the operator, sweeping across the workbench. The air moves in a straight line from the back to the front, carrying any particles away from the sterile workspace.

Horizontal laminar flow cabinets are useful in microbiology labs for sterile media preparation and microbiological testing.

Additional Features

Positive Pressure: Laminar airflow cabinets are maintained at a slight positive pressure relative to the outside environment. This positive pressure prevents contaminated air from entering the cabinet.

UV Light Sterilization: Many laminar airflow cabinets are equipped with ultraviolet (UV) lights that can be switched on when the cabinet is not in use. The UV radiation helps sterilize interior surfaces by killing microorganisms.

Work Surface: The work area is usually made of stainless steel to facilitate easy cleaning.

Limitations of Laminar Airflow Cabinets

Despite their ability to maintain sterile conditions for samples, laminar airflow cabinets do not protect the operator or the environment from potentially harmful aerosols or pathogens. Because the air flows out toward the user in the case of horizontal cabinets or is not contained in a way that protects the operator, laminar airflow cabinets should only be used with non-infectious or low-risk materials.

What is a Biosafety Cabinet?

A Biosafety Cabinet (BSC) is a specialized laboratory enclosure designed to protect the operator, the environment, and the product (the material being worked on). Unlike laminar airflow cabinets, biosafety cabinets are designed to handle hazardous or infectious materials safely.

Biosafety cabinets are critical in clinical labs, pharmaceutical manufacturing, biomedical research, and any setting where containment of infectious agents is required.

How Does a Biosafety Cabinet Work?

Biosafety cabinets utilize HEPA filters similar to laminar airflow cabinets, but their airflow design is far more complex and designed for safety at multiple levels.

- Air flows into the cabinet through the front opening, protecting the operator from exposure.

- Inside, airflow patterns separate contaminated air from clean air zones.

- The air is filtered twice or even three times, depending on the cabinet class.

- Exhaust air passes through a HEPA filter before it reaches the environment.

Classes of Biosafety Cabinets

Biosafety cabinets are classified into three main classes (Class I, II, and III) based on the level of protection they provide.

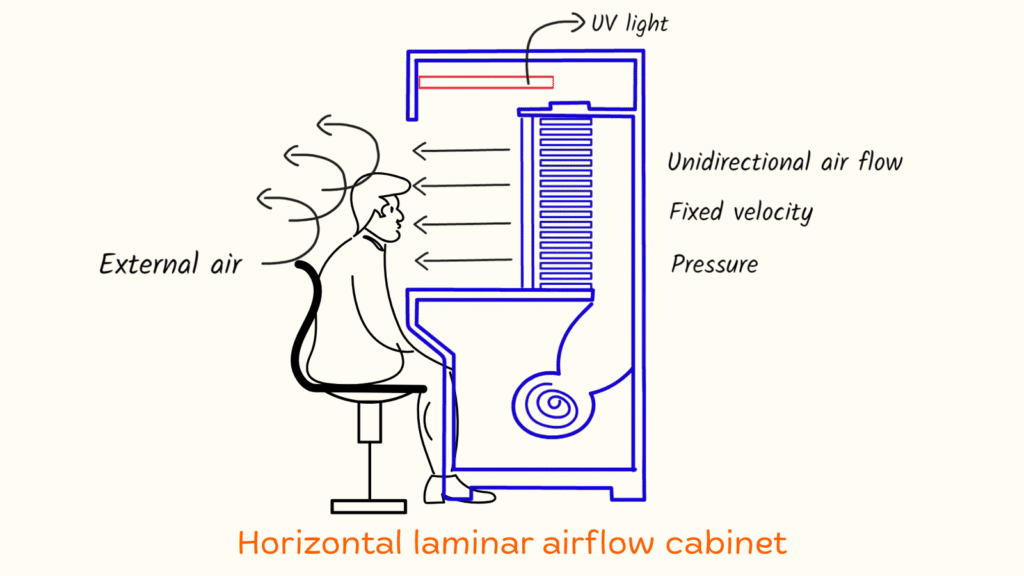

Class I Biosafety Cabinets

Class I biosafety cabinets protect the operator and the environment, not the product being handled. Air is drawn into the cabinet from the operator’s side and moves away from the operator, carrying particles with it.

Before being discharged into the environment, the air is filtered through a HEPA filter. However, because the surrounding air comes into direct contact with the product on the work surface, there is a risk of product contamination.

Thus, Class I cabinets protect the operator and the environment, not the product.

Class II Biosafety Cabinets

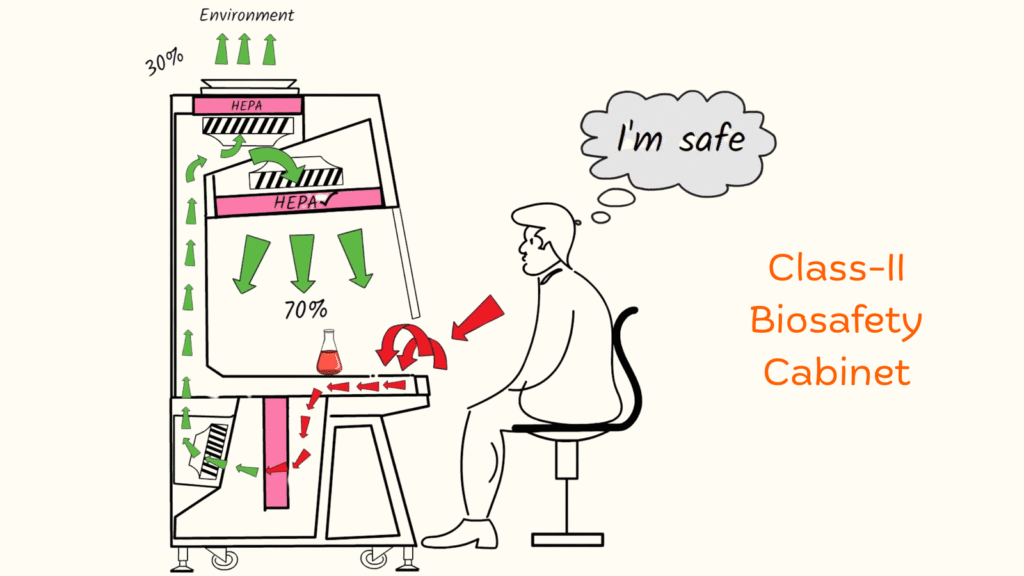

Class II biosafety cabinets, on the other hand, pull air into the cabinet through a front grille. Unlike laminar airflow cabinets, where the airflow is directed toward the operator, here, the dirty air is drawn from the operator’s side, ensuring operator safety (Refer to picture).

Contaminated air is then directed below the workbench and up into a plenum before passing through a HEPA filter. Almost 30% of the air is discharged into the environment after passing through the HEPA filter, while the remaining 70% is recirculated into the cabinet after passing through another HEPA filter.

Class II biosafety cabinets provide:

- A front opening with continuous inward airflow.

- HEPA-filtered, vertical, unidirectional airflow on the working surface.

- HEPA-filtered air to the surrounding area.

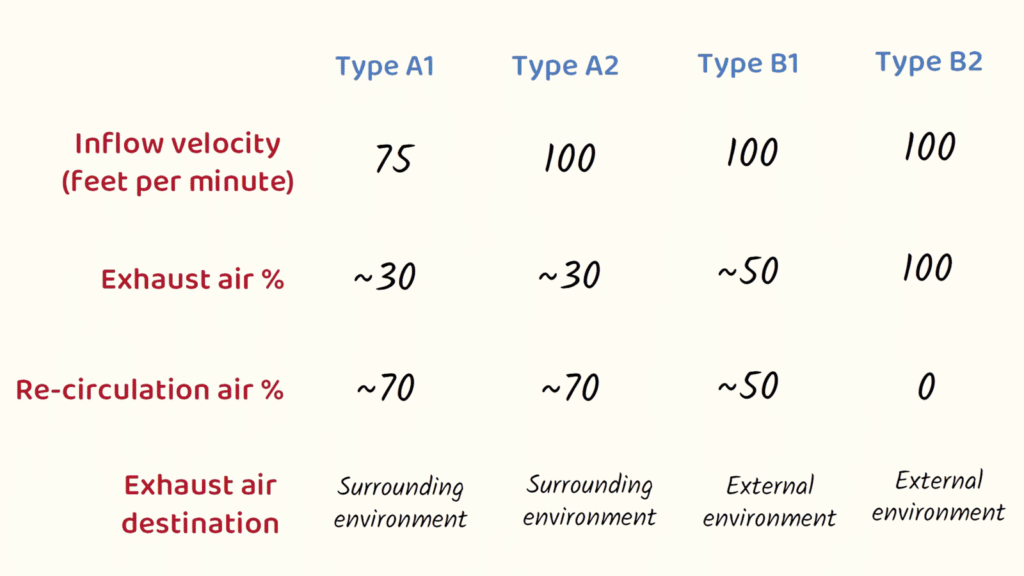

Class II cabinets are subdivided into four types based on exhaust systems and airflow specifics:

- Type A1

- Type A2 (most common)

- Type B1

- Type B2

Class III Biosafety Cabinets

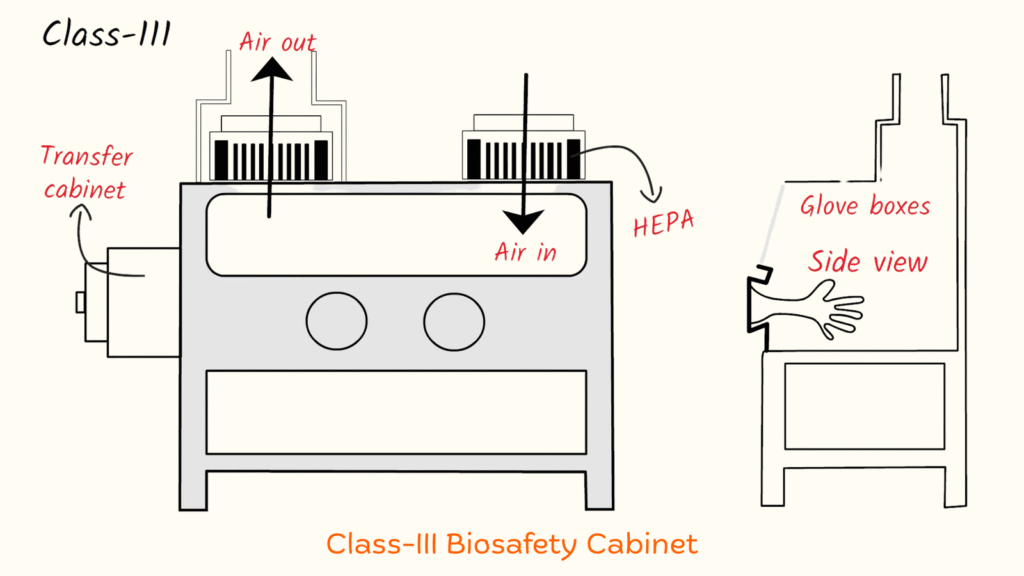

Class III biosafety cabinets are fully enclosed containers equipped with gloves attached to the system, allowing the operator to perform tasks without direct contact. These cabinets are often referred to as “glove boxes.” Both incoming and outgoing air passes through HEPA filters.

Additionally, Class III cabinets feature a transfer chamber that allows the sterilization of materials before they exit the glove box. Exhaust air is treated with either double HEPA filters or a single HEPA filter followed by incineration.

Class III biosafety cabinets provide complete protection to the operator, the environment, and the product, making them suitable for all biosafety-level organisms.

Detailed Comparison: Laminar Airflow Cabinets vs. Biosafety Cabinets

| Feature | Laminar Airflow Cabinet | Biosafety Cabinet |

| Primary Purpose | Protect samples from contamination | Protect samples, operator, and environment |

| Protection Level | Protects product only | Protects product, operator, and environment |

| Airflow Direction | Unidirectional (vertical or horizontal) | Complex, multi-directional with inward flow |

| Use of HEPA Filters | Yes, on supply air only | Yes, on supply and exhaust air |

| Operator Protection | No | Yes |

| Environmental Protection | No | Yes |

| Positive or Negative Pressure | Positive pressure inside cabinet | Negative or balanced pressure to contain agents |

| UV Light Sterilization | Often included | Included in some models |

| Applications | Non-hazardous sterile work | Handling infectious or hazardous materials |

| Typical Settings | Microbiology, electronics, sterile pharmaceutical prep | Clinical labs, research, pharmaceutical manufacturing |